What are steel light poles?

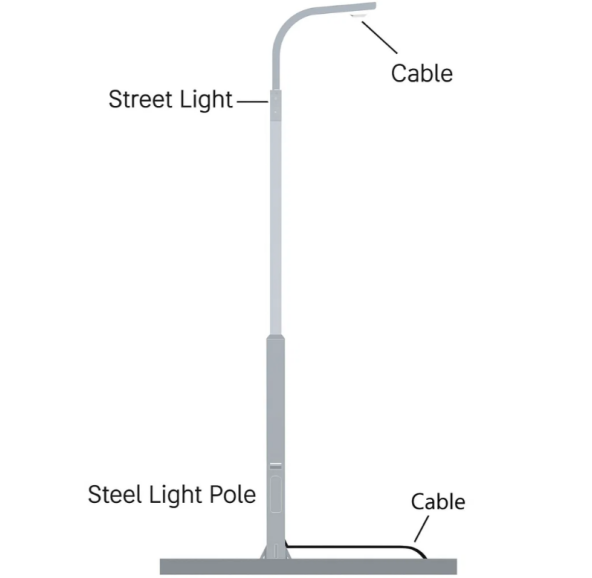

Steel light poles are columnar structural components made primarily of high-quality carbon structural steel plates (such as Q235 and Q345), processed through precision techniques such as cutting, bending, and automatic welding. They are not only the foundational supports for LED streetlights, solar panels, or monitoring equipment, but also an indispensable safety guarantee in urban infrastructure.

Our steel light pole designs aim to achieve a perfect combination of strength and aesthetics, making them a core component of road lighting poles, high-mast lights, and other complex custom steel pole projects. Their superior physical properties, especially their extremely high resistance to pressure and wind, make them key to achieving long-life lighting systems.

What are the differences between steel and aluminum light poles?

Aluminum light poles are another common choice for light pole materials. However, there are fundamental differences between the two in terms of performance, cost, and long-term maintenance, which directly affect the long-term investment and safety of lighting projects. Here are the four core advantages of steel light poles compared to aluminum light poles:

1. Strength and Safety Stability

Steel light poles: Possess extremely high strength and load-bearing capacity, easily withstanding strong wind pressure and huge loads. This makes steel poles the first choice for ultra-high-mast lighting, urban main roads, and complex lighting projects requiring the integration of multiple devices, ensuring absolute safety in extreme weather conditions.

Aluminum light poles: Relatively lower strength, more suitable for low-load landscape lighting or courtyard environments.

2. Durability and Long-Term Corrosion Resistance

Steel light poles: Our products are treated with hot-dip galvanizing anti-corrosion technology, ensuring an ultra-long service life, generally exceeding 30 years. This protective layer is robust and reliable, providing long-term protection for outdoor lifespan.

Aluminum light poles: Although aluminum has a certain degree of corrosion resistance, its structural strength and wear resistance are not as good as galvanized steel, and its long-term stability is relatively low.

3. Maintenance and Economic Benefits

Steel light poles: While having a moderate initial cost, their greatest economic advantage lies in their high repairability. Localized damage can be repaired through professional welding, making maintenance costs far lower than replacing the entire pole. This makes steel light poles a representative of high-performance, cost-effective light poles.

Aluminum light poles: Once structurally damaged, they often require complete replacement, resulting in high maintenance costs and failing to meet the principle of long-term investment efficiency.

4. Application Scope and Functionality

Steel light poles: Suitable for environments with high reliability and functionality requirements, such as urban roads, highways, airports, ports, and large public places. Their structural design facilitates the integration of smart lighting and monitoring equipment.

Aluminum light poles: More concentrated in landscape locations with high decorative or aesthetic requirements.

How do our steel light poles achieve a lifespan exceeding 30 years through hot-dip galvanizing and anti-corrosion technology?

In outdoor lighting projects, the lifespan and corrosion resistance of light poles are key indicators of their long-term value and reliability. As a professional steel light pole manufacturer, we understand that simply using high-quality steel is insufficient; superior anti-corrosion technology is essential to ensure an exceptionally long lifespan. Our core secret to achieving a product lifespan exceeding 30 years lies in the rigorous implementation of the hot-dip galvanizing process, combined with an advanced dual anti-corrosion protection system.

I. The Cornerstone of Longevity: Hot-Dip Galvanizing Process Analysis

Hot-dip galvanizing is currently recognized as one of the best methods for steel corrosion protection. It is not a simple surface coating, but rather a process that uses physicochemical reactions to form a robust zinc-iron alloy layer on the surface of the steel light pole, achieving a metallurgical bond with the substrate.

1. Metallurgically Bonded "Sacrificial Anode" Protection

After the precise steel pole customization and welding are completed, the light pole is immersed in molten zinc. At high temperatures, iron and zinc diffuse into each other, forming a multi-layered zinc-iron alloy layer on the steel surface.

- Strength: This alloy layer is harder than the steel itself, possessing extremely strong resistance to mechanical damage.

- Sacrificial Anode Protection: The zinc layer acts as a "sacrificial anode." When the coating on the steel surface is damaged by impact, the zinc preferentially corrodes itself to protect the internal steel from rust.

2. Stringent Standards for Galvanized Layer Thickness

Based on international standards and the operating environment of road lighting poles, we strictly control the thickness of the hot-dip galvanized layer. Typically, the galvanized layer thickness of high-quality hot-dip galvanized light poles can reach over 85 micrometers, providing a reliable technical guarantee for a steel pole lifespan of 30 years or longer.

II. Double Protection: Powder Coating/Painting Reinforcement

To further enhance protective performance and meet the needs of urban aesthetic design, after completing the hot-dip galvanizing process, we also apply an additional electrostatic powder coating (or painting) treatment to the light pole.

- Enhanced UV and Acid Rain Resistance: High-quality outdoor polyester powder coating forms a second physical barrier, resisting UV radiation, preventing powdering, and protecting against acid rain.

- Meeting Diverse Urban Aesthetic Needs: Powder coating offers a rich selection of colors and textures, allowing steel light poles to integrate into the urban landscape while ensuring functionality and reliability.

How does the structural design of steel light poles ensure absolute safety and stability in the face of extreme weather and high wind pressure?

In urban infrastructure construction, safety is paramount. Especially for tall road lighting poles and extra-high mast lighting systems, withstanding extreme natural forces such as high wind pressure, typhoons, and earthquakes is a crucial design and manufacturing challenge.

I. Core of Wind-Resistant Design: From Conical to Variable Diameter Design Philosophy

Our steel light pole structures strictly adhere to national standards and industry specifications, achieving wind resistance far exceeding that of ordinary outdoor facilities.

1. Optimized Cross-Section and Taper Design

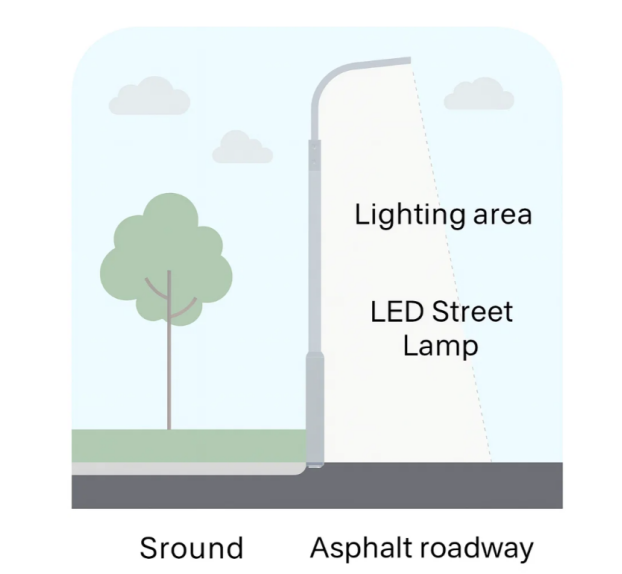

Light poles typically employ a variable diameter design, a tapered structure that gradually tapers from bottom to top. This design reduces wind resistance area, balances stress distribution, and ensures significant wind stress is evenly transmitted to the foundation.

2. Precise Matching of Steel Strength and Thickness

Based on the height of the light pole, the wind pressure at the installation location, and the weight of the overhead equipment, we select high-strength, high-quality steel, such as Q235 or Q345 steel. The wall thickness and diameter are calculated to ensure sufficient safety margins under design wind speeds.

II. Stability Guarantee of Welding Process and Foundation Connection

- Quality Control of Fully Automated Welding: Fully automated welding ensures weld strength and consistency, followed by non-destructive testing to eliminate internal defects.

- Anchor Foundation and Flange Connection: Thickened and enlarged flanges, combined with strict foundation design, ensure firm pole fixation, effectively resisting pull-out forces and overturning moments.

What complex application needs, from urban roads to ultra-high-mast lighting, can steel light poles meet?

I. Comprehensive Coverage of Core Application Scenarios

- Urban Arterial Roads and Highway Lighting: Standard tapered and boom-type light poles ensure safety and reliability for high-intensity traffic and wind loads.

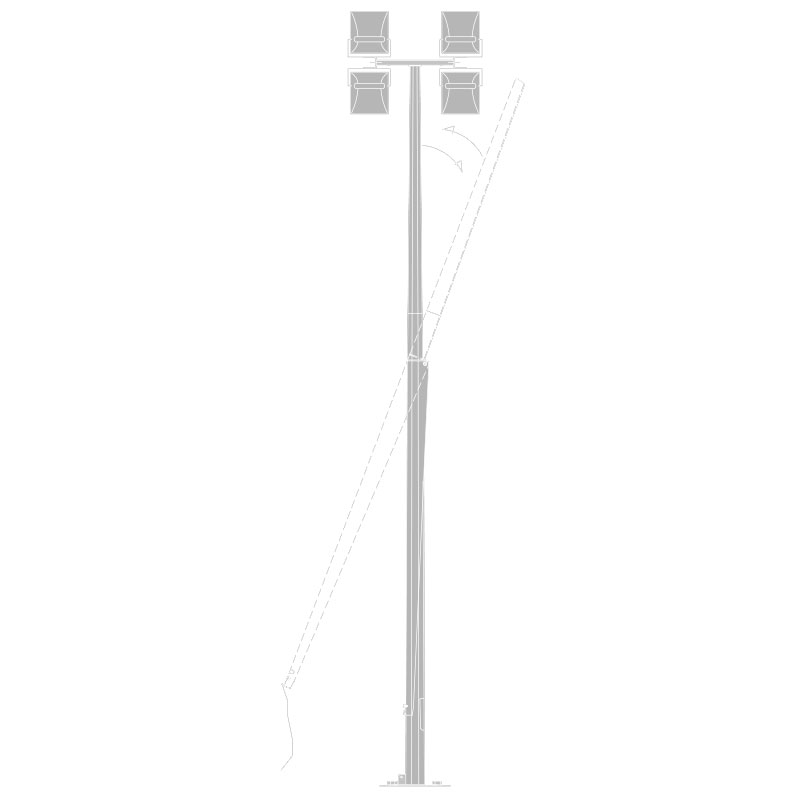

- Extra-High Pole Lighting and Large-Area Floodlighting: Polygonal cross-section extra-high poles, with electric lifting systems, simplify maintenance for airports, ports, stadiums, and urban overpasses.

- Landscape Lighting and Courtyard Locations: Customizable design and powder coating allow steel light poles to meet aesthetic and functional requirements for parks, squares, and commercial streets.

II. Adapting to Future Trends: Multifunctional Integration and Customized Services

- Smart City Function Integration: Integration of 5G micro base stations, WiFi hotspots, environmental sensors, traffic cameras, LED displays, and EV charging interfaces.

- Professional Customized Non-Standard Services: Engineering solutions for unique cross-sections, special mounting methods, and complex terrain projects ensure perfect implementation of lighting projects.

Conclusion: Flexible Adaptability, Enabling Diverse Lighting Needs

Whether for ultra-high pole lighting or multifunctional smart poles, steel light poles provide comprehensive, reliable solutions with unparalleled structural stability, repairability, and ultra-long lifespan. Choosing our steel light poles means choosing a future-oriented, flexible, and cost-effective urban lighting infrastructure.

English

English Español

Español Français

Français عربى

عربى italiano

italiano