In modern urban lighting projects and road lighting, aluminum light poles are gradually replacing traditional steel light poles due to their significant advantages such as light weight, corrosion resistance, high aesthetic appeal, and recyclability. As an important component of smart city construction, high-quality aluminum light poles not only provide stable lighting support but also serve as works of art in the urban landscape.

1. Raw Material Selection: The Foundation of High-Quality Aluminum Alloys

The manufacturing of aluminum light poles begins with the strict selection of raw materials. To ensure the strength and toughness of the pole body, 6000 series aluminum alloys (such as 6061 or 6063) are typically selected. This type of aluminum material has excellent processing performance and oxidation resistance.

Material Inspection: Ensuring that the aluminum composition meets national standards and is free of impurities.

Specification Cutting: Cutting bulk aluminum plates or tubes to predetermined dimensions according to design drawings.

2. Spinning Forming Technology: Creating Seamless Pole Bodies

This is the most crucial step in the production of aluminum light poles. Currently, mainstream production lines use large-scale CNC spinning machines for processing.

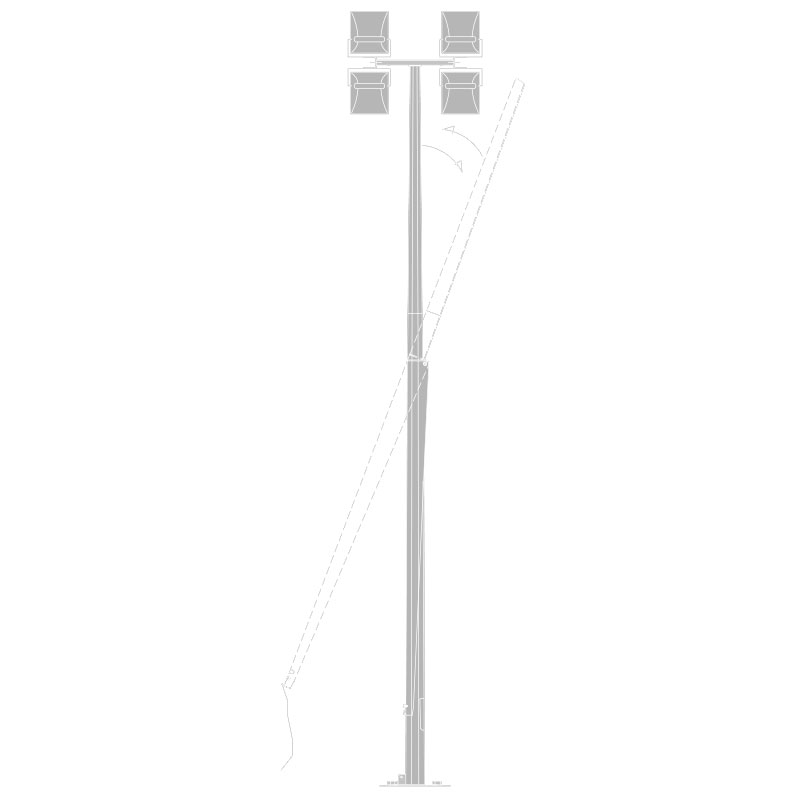

1. Constant Diameter and Variable Diameter: Spinning technology allows cylindrical aluminum tubes to be processed into tapered or large-span variable diameter poles.

2. Seamless Integration: The spinning process makes the aluminum molecular structure more compact, resulting in a smooth, weld-free pole surface. This significantly enhances the structural safety and wind resistance of aluminum light poles.

3. Heat Treatment Process: Enhancing Metal Mechanical Properties

Due to the relatively soft nature of aluminum, the formed light pole requires heat treatment (usually T6 temper) to increase its hardness.

Solution Treatment: Heating the light pole to a specific temperature and holding it there.

Artificial Aging: Precise temperature control and cooling induce the precipitation of strengthening phases within the aluminum alloy, allowing the aluminum light pole to achieve the designed yield strength.

4. Surface Treatment: Dual Protection of Aesthetics and Corrosion Resistance

The popularity of aluminum light poles in landscape lighting is largely due to their diverse surface treatment options:

Anodizing: Forming a dense oxide film on the surface, which is not only extremely wear-resistant but also presents the unique texture of metal.

Electrostatic spraying: Uses outdoor-grade powder coating, offering a rich variety of colors, and can be customized to meet urban planning needs.

Fluorocarbon paint: Provides exceptional weather resistance, maintaining its color and preventing peeling for years, even in salt spray environments near the sea.

5. Precision Machining and Assembly

After the pole is formed, a series of post-processing steps are required:

Inspection hole drilling: Precisely drills electrical access holes using laser cutting technology for later installation of ballasts or smart control modules.

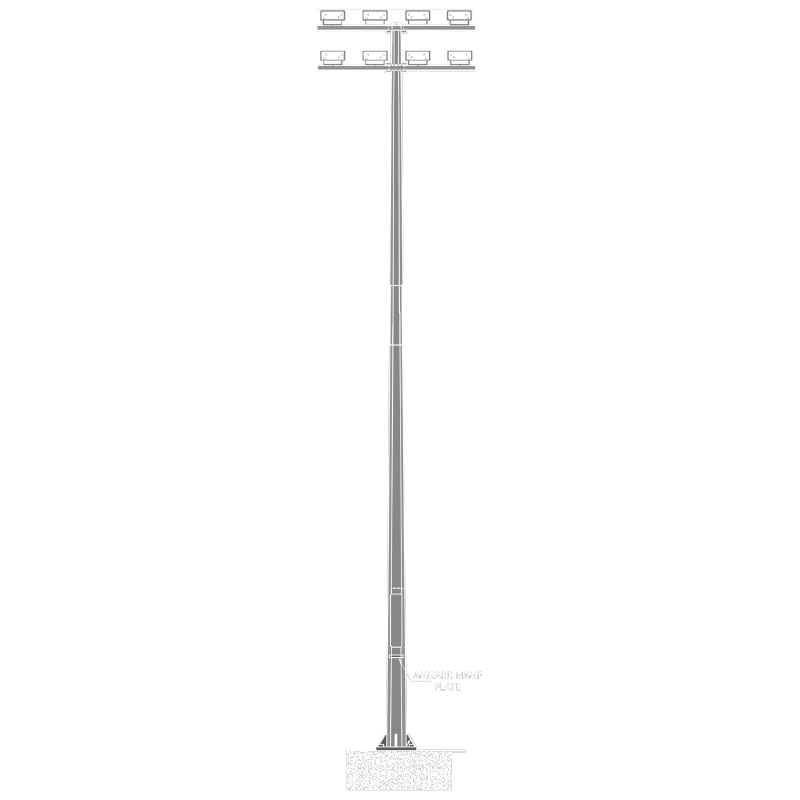

Flange welding: Welds the reinforced base flange to the pole, ensuring the aluminum light pole is stable and reliable during installation.

Factory inspection: Includes verticality testing, coating thickness testing, and salt spray testing.

Why choose aluminum light poles?

Compared to traditional materials, aluminum light poles offer the following core advantages:

Lightweight: Easier installation and transportation, reducing construction costs.

Maintenance-free: The oxide layer formed on the aluminum surface is self-healing, minimizing rust problems.

Environmentally friendly: Aluminum has a recycling rate of over 95%, aligning with green development principles.

From material selection to forming, from heat treatment to exquisite surface coating, every aluminum light pole embodies the superb craftsmanship of modern industry. With the widespread adoption of smart streetlight technology, aluminum alloys, due to their excellent thermal conductivity and ease of processing, will undoubtedly play a more important role in the future of urban lighting.

English

English