What are Aluminum Light Pole?

In modern urban construction and outdoor lighting, the role of streetlight poles has far exceeded lighting itself. With increasing demands for urban aesthetics, environmental protection, and durability, a new material is rapidly becoming the focus of the industry—Aluminum Light Pole.

I. Material Upgrade: Why Choose High-Performance Aluminum Alloy?

Aluminum alloy streetlight poles, as the name suggests, are poles made of high-strength, corrosion-resistant aluminum alloy. Due to its unique physical and chemical properties, aluminum perfectly meets the stringent requirements of modern outdoor lighting solutions:

Lightweight Advantage:

Aluminum has a much lower density than steel, giving Aluminum Light Pole significant lightweight characteristics. This greatly simplifies transportation and installation, reduces labor and machinery costs, and improves construction safety.

Superior Corrosion Resistance:

A dense oxide film naturally forms on the surface of aluminum alloy, providing a natural anti-corrosion barrier. This makes it perform exceptionally well in harsh environments such as coastal areas, rainy climates, or areas with severe salt spray corrosion, which is unmatched by cement poles and ordinary steel poles.

Green and Environmentally Friendly:

Aluminum has extremely high recycling value, and scrapped aluminum poles can be almost 100% recycled, aligning with the environmental trends of sustainable urban development and "zero-carbon" lighting.

II. Core Technology: Reliability Meeting International Standards

The value of a high-quality aluminum street light pole lies not only in the material itself, but also in the manufacturing process. Welding technology is crucial in determining the lifespan and structural safety of aluminum poles.

Our aluminum light poles are meticulously crafted using professional welding techniques certified by the Canadian Welding Bureau. This means our street light pole welding standards meet the highest international requirements.

Key Advantage: Certified welding technology ensures the consistency, strength, and long-term safety of the pole structure, far exceeding products manufactured using ordinary processes.

III. Quality Commitment: Extended Warranty of Up to 25 Years

Choosing aluminum alloy street light poles means investing in long-term stability and low maintenance costs. Our confidence in our products is reflected in our industry-leading warranty commitment:

- Anodized Aluminum Poles vs. Satin-Brushed Aluminum Poles

For aluminum poles with anodized or satin-brushed finishes:

We offer a warranty of up to 25 years. This surface treatment is not only aesthetically pleasing but also further enhances the aluminum's weather resistance and scratch resistance.

- Powder Coated Aluminum Poles (High-Performance Coating)

For powder coated aluminum poles requiring personalized colors, we offer a layered warranty:

- Paint Warranty: A 5-year paint warranty is provided from the date of shipment. The warranty covers cracking, peeling, excessive discoloration, and fading caused by exposure to normal weather conditions, ensuring a long-lasting new appearance.

- Aluminum Poles Warranty: We offer a 25-year warranty on the lifespan and structural stability of the core aluminum pole.

Aluminum street light poles are not merely a material replacement; they represent a comprehensive upgrade in urban lighting towards lighter, more durable, more environmentally friendly, and more economical options. With superior corrosion resistance, internationally certified welding technology, and a 25-year warranty commitment, they have become the most reliable outdoor lighting solution for modern cities and "smart city" construction.

How do aluminum street light poles ensure superior wind and earthquake resistance?

Aluminum Light Pole achieve their superior wind and earthquake resistance by combining material properties, structural design, and manufacturing processes, successfully overcoming concerns about insufficient strength due to their lightweight nature.

1. Material Properties and Enhanced Strength

Although aluminum has a low density (light weight), its alloys possess excellent strength characteristics:

- High-strength Aluminum Alloys: The aluminum used in manufacturing street light poles is typically selected from specific high-strength aluminum alloy grades (such as the 6061 or 6063 series). These alloys, after heat treatment, can achieve yield strengths approaching or even exceeding those of some steels.

- Excellent Ductility: Aluminum alloys possess good ductility. When encountering the enormous instantaneous stress generated by strong winds or earthquakes, aluminum can absorb energy and undergo controlled plastic deformation, rather than fracturing instantly like brittle materials, thus improving the overall resilience of the system.

- Lightweight and Low Inertia: The lightweight nature of aluminum poles results in lower inertial forces (F = m * a, where m is mass) under wind loads or seismic forces. Inertial forces are the primary source of seismic forces on a structure; lower inertial forces mean less damage to the foundation.

2. Structural Design Optimization

Design is crucial for ensuring wind and earthquake resistance:

- Tapered Design: Modern Aluminum Light Pole often employ a tapered structure, with the pole gradually tapering from bottom to top. This design is not only aesthetically pleasing but, more importantly, optimizes structural stress, maximizing the moment of inertia at the base of the pole (where stress is greatest), effectively resisting bending moments.

- Cross-section Optimization: Designers use precise calculations to determine the thickness and diameter variations of the pole, providing the necessary bending and shear resistance with minimal material usage, ensuring structural safety under predetermined wind speeds and seismic intensities.

- Basic Connection: The connection between the pole and the foundation (such as flange connection) is specially designed and reinforced to ensure that the connection point will not fail before the pole or foundation under extreme loads.

3. Welding and Manufacturing Process Assurance

The Canadian Welding Bureau certification mentioned in your product description is a key guarantee of quality and performance:

- Authoritative Welding Certification: Welding aluminum alloys is more difficult than welding steel. Obtaining welding technology such as Canadian Welding Bureau certification means that the quality, strength, and durability of the welds meet the highest international standards. Welds are a critical weak point in the streetlight pole structure; high-quality welding ensures that the welds will not crack or fail when the pole is subjected to high wind loads and vibrations.

- Strict Tolerance Control: The geometry and thickness tolerances of the pole are strictly controlled to ensure that the actual load-bearing capacity of the pole is consistent with the design calculations.

Through the synergistic effect of these three aspects, aluminum street light poles can meet or even exceed the performance requirements of traditional materials under the same wind speed and seismic intensity, providing superior wind resistance (typically able to withstand typhoons of up to level 10-17) and seismic resistance (meeting the prescribed seismic intensity fortification standards).

What are the surface treatment processes for aluminum street light poles, and which is the most durable?

The durability and aesthetic longevity of aluminum street light poles largely depend on their surface treatment processes. Compared to traditional materials, aluminum itself has excellent corrosion resistance, while professional surface treatments provide additional protection, aesthetics, and long-term weather resistance.

The mainstream surface treatment processes for aluminum street light poles mainly include anodizing, satin brushing, and powder coating.

1. Anodizing

What is anodizing? Anodizing is the process of forming a hard, dense aluminum oxide film on the surface of aluminum through an electrochemical reaction. This film is an integral part of the aluminum material itself, not a simple coating.

Durability Features:

- Exceptional Corrosion Resistance: The high hardness and chemical stability of the oxide film effectively resist acid rain, salt spray, and UV radiation, making it particularly suitable for coastal or heavily polluted industrial areas.

- High Hardness and Abrasion Resistance: Increases the surface hardness of the aluminum, making it less prone to scratches.

- Appearance: Available in a variety of colors, but typically featuring a metallic finish.

- Warranty Commitment: Our anodized aluminum rods come with a 25-year warranty, demonstrating confidence in the long-lasting protective capabilities of this process.

2. Satin Brush Finish

What is Satin Brush Finish? Satin brush finish is a physical processing technique that creates a uniform, silky texture on the surface of aluminum through grinding or brushing. This is often used as a pre-treatment or final aesthetic finish.

Durability Features:

- Metallic Texture: Provides a soft, elegant matte metallic look that effectively conceals minor scratches.

- Basic Corrosion Protection: Satin brushed finish is typically used in conjunction with other corrosion protection measures (such as clear varnish or anodizing) to ensure long-lasting protection. Satin brushing alone is primarily for aesthetic purposes.

- Warranty Commitment: Our satin brushed aluminum rods (usually referring to products with a reliable anti-corrosion coating) also come with a 25-year warranty.

3. Powder Coating

What is powder coating? Powder coating involves electrostatically adsorbing dry powdered paint onto the aluminum surface, followed by high-temperature baking and curing to form a robust organic coating.

Durability Features:

- Color Variety: Offers the widest range of color choices to meet urban landscape or customized needs.

- Thick Coating Protection: Uniform coating thickness effectively isolates the material from the external environment and provides excellent UV resistance.

- Environmental Advantages: Powder coatings do not contain organic solvents, making them more environmentally friendly.

- Warranty Commitment:

- Paint Appearance Warranty: The paint is covered by a 5-year warranty from the date of shipment. The warranty covers cracking, peeling, excessive discoloration, and fading caused by exposure to normal weather conditions.

- Aluminum shaft warranty: The core aluminum shaft structure is unaffected by the paint finish and enjoys a 25-year warranty.

How much installation time and labor costs can aluminum street light poles save?

In urban infrastructure construction, especially in large-scale outdoor lighting solutions projects, efficiency is money. Traditional steel or concrete street light poles, due to their enormous weight, not only increase transportation difficulties but also pose severe challenges to on-site installation. The emergence of Aluminum Light Pole, with their core lightweight advantage, is completely changing the installation process, bringing significant economic benefits to municipal engineering and construction companies.

I. Core Advantage: How does lightweight translate into cost savings?

Aluminum alloy street light poles are made of high-strength aluminum alloy, with a density only about 1/3 that of steel. This significantly reduces the weight of aluminum poles of the same specifications.

This lightweight advantage directly translates into three major cost savings:

1. Reduced transportation and handling costs

Reduced load: A truck can carry more aluminum street light poles, reducing the number of trips and corresponding fuel costs.

2. Easy On-Site Operation:

The lightweight nature of aluminum poles allows workers to move them from storage points to installation locations more quickly, reducing reliance on large handling equipment (such as forklifts).

3. Significantly Reduced Installation Time:

This is the most rewarding aspect of Aluminum Light Pole.

- Reduces Reliance on Machinery: For small to medium-sized aluminum poles, the need for heavy-duty cranes can be eliminated, allowing for the use of light cranes or manual labor to assist in pole erection.

- Simplified Process: The lighter weight means faster positioning and vertical adjustments, reducing the risk and difficulty for workers.

- Increased Efficiency: Experience shows that using aluminum alloy streetlight poles can reduce installation time by 30% to 50% compared to steel poles, especially in areas with scattered installation points or limited traffic.

Optimized Labor Costs: A streamlined team: Installing the same batch of streetlights requires fewer on-site installation and support workers due to the reduced operational difficulty, thus saving on labor costs.

Simplified Operations: Enhanced Safety: The lightweight poles reduce the risk of workplace injuries when workers handle heavy objects, indirectly lowering project management costs.

II. "Hidden" Savings Throughout the Life Cycle

Beyond the initial installation, the lightweight nature of aluminum poles continues to generate benefits throughout the entire lifespan of the streetlight pole:

- Simplified Infrastructure: Due to the light weight of Aluminum Light Pole, their foundation requirements are lower than those for heavy steel or concrete poles, potentially allowing for smaller and simpler foundations, further reducing foundation construction costs.

- Easy Future Maintenance: Even when future maintenance or replacement is needed, the lightweight aluminum poles mean that maintenance teams can operate more quickly and flexibly.

- Sustainability: The high recycling value and environmentally friendly properties of aluminum provide additional sustainability value for the project.

Choosing Aluminum Light Pole is essentially an investment in installation efficiency and project lifecycle management. In the current wave of "new infrastructure" and urban lighting upgrades, the ability to complete large-scale installations quickly, safely, and at low cost is key to project success. Aluminum alloy street light poles offer more than just excellent durability (such as a 25-year warranty); they provide a modern outdoor lighting solution that optimizes construction processes, significantly saves labor costs, and reduces installation time.

What technical parameters and quality certifications should be prioritized when purchasing aluminum street light poles?

When purchasing aluminum street light poles, the following technical parameters, quality certifications, and warranty documents should be prioritized to ensure the product meets safety and durability standards.

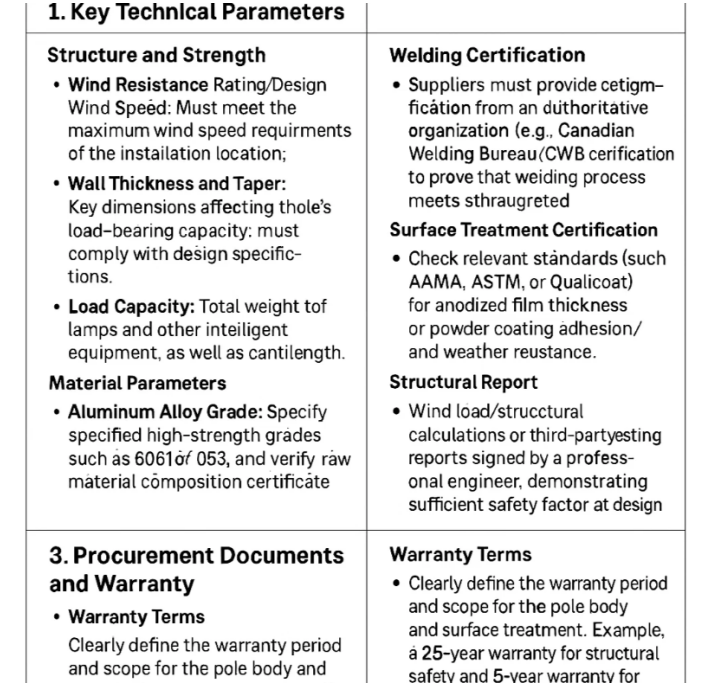

1. Key Technical Parameters

Structure and Strength:

- Wind Resistance Rating/Design Wind Speed: Must meet the maximum wind speed requirements of the installation site; this is the most important safety indicator.

- Wall Thickness and Taper: Critical dimensions affecting the pole's load-bearing capacity; must comply with design specifications.

- Load Capacity: The total weight of the luminaire and other smart equipment, as well as the cantilever length, must be considered.

Material Parameters:

- Aluminum Alloy Grade: Clearly specify the high-strength grade used, such as 6061 or 6063, and verify the raw material composition certificate.

2. Key Quality Standards and Certifications

- Welding Certification: Suppliers must provide welding certification from an authoritative body (e.g., Canadian Welding Bureau (CWB) certification) to demonstrate that the welding process meets the highest international standards and ensures structural integrity.

- Surface Treatment Certification: Check relevant standards (e.g., AAMA, ASTM, or Qualicoat) for anodized film thickness or powder coating adhesion and weather resistance.

- Structural Report: Require wind load/structural calculations or third-party testing reports signed by a professional engineer, demonstrating sufficient safety factor at the design wind speed.

- Management System: Suppliers should possess ISO 9001 quality management system certification.

3. Procurement Documents and Warranty

- Warranty Terms: Clearly define the warranty period and scope for the pole body and surface treatments. For example, a 25-year warranty for structural safety and a 5-year warranty for powder coating appearance.

- Materials Documentation: Require factory inspection reports for raw materials to verify the chemical composition of the aluminum alloy.

English

English Español

Español Français

Français عربى

عربى italiano

italiano